Introduction

This document describes the functionality of E-WMS SSCC Shipment Tracing,

as per product update 409.

Description

SSCC Shipment Tracing, introduced in release 405, offers the possibility to track & trace

fulfillments done with E-WMS and when using SSCC registration.

With SSCC Shipment Tracing you can:

- track movements of SSCC's by scanning different sources and targets for

a SSCC during the shipping process

- validate whether all expected SSCC's are scanned as part of a shipment;

based on the assumption that all SSCC's for one delivery debtor and one

delivery date are in one shipment number

- report your scanned SSCC movements based on several selections

Shipment Tracing has no Control Center as other WMS processes do, since this

is an scanner application only. There is a report available to view SSCC

shipment history.

Preconditions

- License:

- SE1380 E-WMS I (or SE5700 Pick-IT Basic + SE5760

Pick-IT RF)

- SE1385 E-WMS Terminal User (or SE5791 Pick-IT Terminal User)

- Communication type: ASP

- SSCC registration enabled in WMS SSCC settings ('scanned' or

'generated' SSCC)

Using E-WMS SKU Management is not required to

use SSCC Shipment Tracing. SKU Management and SSCC are not necessarily related,

but it is possible to use SKU numbers as SSCC numbers in E-WMS SSCC scanning.

Using E-WMS

Autopack or Shipment Builder is not required to use SSCC Shipment Tracing,

but you could use SSCC Shipment Tracing for SSCC numbers generated in Autopack.

Typically, Autopack will be used when not using hand terminals for order

picking, and SSCC Shipment Tracing can only be used on hand terminals.

Terms and entities used in SSCC Shipment Tracing

- Shipment number: a unique

(SSCC) number assigned to a batch of shipped goods of one delivery debtor

and one delivery date, which can consist of one or more outer SSCC's.

- SSCC number: an 18 digit

number, as prescribed by the

GS1

organization, used to uniquely identify goods shipped between trading

partners

- (Outer) SSCC: a pallet or

other larger stock keeping unit, which can hold one or more sales units, or

"inner SSCC's"

- Inner SSCC: a box or other

stock keeping unit, which holds one or more sales units, and can be stacked

on an outer SSCC

- Source: a 'location' or dock,

where SSCC's where placed before transferring them. In SSCC Shipment Tracing

this is not a real warehouse location, and the scanned value is not

validated. It is intended for 'registration' and reporting only.

- Target: a 'location', dock,

load carrier or truck, where SSCC's are moved to. In SSCC Shipment Tracing

this is not a real warehouse location, and the scanned value is not

validated. It is intended for 'registration' and reporting only.

Rules

- You can only scan SSCC numbers which are part of

processed fulfillments

- You can only work at one shipment at a time on a

hand terminal, until you leave and select the 'Scan shipment' function

again.

- When using recurring SSCC numbers (for example,

crates with RFID chip and bar code) in your fulfillment procedure, the

most recent delivery note for that SSCC will be used to link with the

current scanned shipment

- One shipment:

- can only be used for one delivery debtor for one delivery date

- can hold multiple SSCC's

- One SSCC:

- can only be in one shipment per date (scan date)

- can be scanned with different sources and/or targets for the same

shipment

Configuration

To provide access to the ASP scanner menu for SSCC Shipment Tracing scanning, you

first need to enable

the setting 'SSCC shipment tracing' in menu System, E-WMS,

Scanners, General scanner settings.

Next, you can configure the functionality of SSCC Shipment Tracing in menu

System, E-WMS, Scanners, SSCC shipment tracing settings.

This document describes these hand terminal settings.

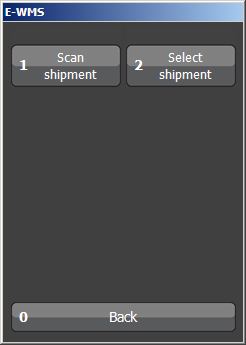

Hand terminal: menu

When general hand terminal setting 'SSCC Shipment tracing' is enabled, SSCC Shipment Tracing is integrated

as submenu in ASP hand terminal menu Orders. Select menu

'Orders, Shipments' to show the submenu:

Scan shipment: this menu allows you

to scan SSCC's and link these to shipment numbers. The shipment number is either

scanned or automatically generated.

Select shipment: this menu allows you to

first select a previously scanned shipment number and continue scanning for that

selected shipment.

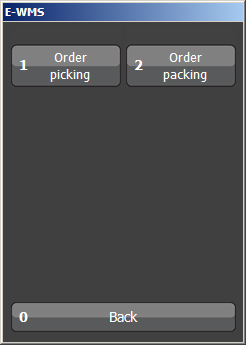

When SSCC Shipment Tracing is enabled, you will have to

select one extra menu to start order picking.

For order picking or packing, please select menu 'Orders, Order picking'

first:

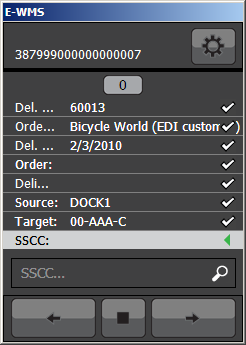

Shipment scanning screens

Depending on your configured hand terminal settings, you can scan the

following fields in ASP menu Orders, Shipments, Scan Shipment:

- Shipment number

The shipment number identifies which group of pallets for the same

debtor and same delivery date is now being scanned.

This number needs to be scanned when the setting 'SSCC number' is set to

'Scan', so then it is assumed you already have a shipment number bar code

label available.

When the

setting 'SSCC number' is set to 'Generate', then a shipment number will be

automatically generated (and applied) after scanning the first pallet SSCC

number.

When continuing scanning SSCC's for an existing shipment, you need to make sure to scan the same shipment number as used earlier, unless you are

indeed using different shipment numbers for the same debtor.

It is possible to scan different shipment numbers for the same debtor on the

same day, but only when 'scanning' shipment numbers. When generating

shipment numbers, all pallets for one debtor will get the same shipment

number.

Currently there is no validation on the length of the scanned shipment

number, but it would be best practice to use 18 digit SSCC numbers.

- Reference

The reference field can be skipped or scanned, depending on the hand

terminal settings.

This reference is assigned to the shipment, and not per single pallet, and

can be left empty.

The following fields can be scanned repeatedly, depending on the hand

terminal setting 'Focus to':

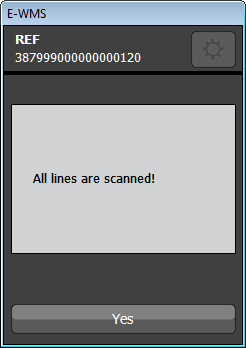

All lines are scanned

Following message will show after you scanned the last SSCC

for the shipment you were working on:

This message will only show when the scanner setting 'Validate complete

shipment' is enabled.

STOP button

When pressing the STOP button you can indicate that you are done. A shipment

is however not set to 'ready' as would be usual with other WMS

transactions like orderpicking, you can continue scanning for the same shipment

later.

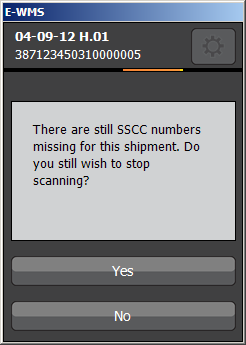

When the hand terminal setting 'Validate: shipment complete' was enabled, and

there are still SSCC's in WMS order history for the same delivery debtor and

delivery date which are not scanned now, you will see the message "There

are still SSCC numbers missing for this shipment. Do you still wish to stop

scanning?".

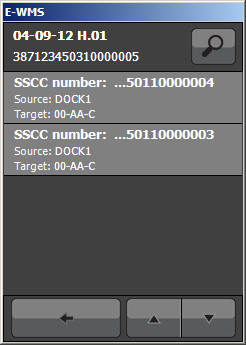

OPTIONS / EDIT and DELETE button

After scanning one or more SSCC's, you can view, edit or delete the scanned

SSCC numbers:

The options menu can be used during scanning, or you can use hand

terminal menu 'Select shipment' to view or edit an existing shipment.

Reporting

A report is provided to select and report the scanned shipments. Please refer

to

this document for more details.

Related documents