This document describes the configuration and workings of E-WMS "Order

Pick&Pack", as available in release 416.

E-WMS already offered

Pick&Pack for some time. This method, called "Bulk Pick&Pack" from release

411, uses E-WMS Replenishment for the first stage, and E-WMS fulfilment for the

second stage. When using "Order Pick&Pack", introduced in release

411, only one control center is used.

Prerequisites

see document 'Pick

& Pack', section 'Requirements'.

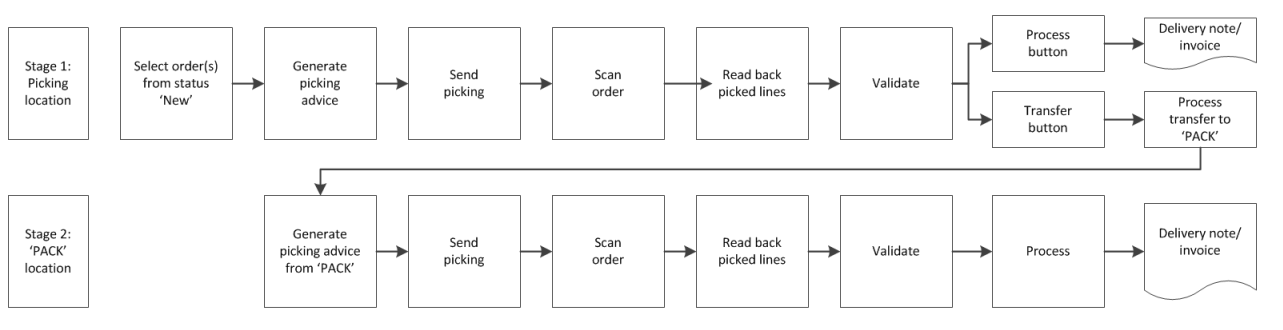

Basic process of Order Pick&Pack

In Order Pick&Pack, each order item is scanned twice: in stage 1 from the

picking locations and in stage 2 from the general packing location. At the end

of stage 1, after validation in the control center or by the WMS service, the

order can either be 'transferred', or be processed as usual.

When choosing 'transfer', E-WMS will generate and process an E-WMS transfer to

the packing location, and send the order back to status 'Advice', now advising

the packing location.

Configuration of Order Pick&Pack

Process settings

The usage of Order Pick&Pack is configured in menu

System, General, Settings, "WMS Sales order fulfilment" tab, section

"Fulfilment: Pick and Pack".

Another setting is available in the same settings screen, section 'Automatic

validation'.

When the setting "Stock transfers: immediate processing" is enabled, then

picked orders can be automatically be read back, validated and processed as

transfers, either in the control center or by the E-WMS fulfilment RF service.

For the transfer report shown at the end of stage one, following settings are

available in the same settings screen, just above the 'process order' section.

With these new report settings you are able to configure and use a customized

report layout, or disable the transfer processing report.

To activate 'Order Pick&Pack', enable the

setting 'Replenishment order', fill an existing location in 'Packing location' and

configure the setting 'Pick and pack: Type' to 'Order'.

This configuration will have following effect:

- the setting 'Stock transfers: immediate processing' becomes available in

WMS Sales order fulfilment settings, in menu

System, General, Settings

- the setting 'Immediate processing' is disabled, since automatic

fulfilment cannot be used in combination with Order Pick&Pack

- the setting 'Order pick&pack' is available in Exact Globe Next item

maintenance, 'WMS' button

- the setting 'Order pick&pack' is available in Exact Globe Next debtor

maintenance, 'WMS' button

- the button 'Transfer' is visible in control center Sales order

fulfilment

- the column 'Transferred' is now visible in control center Sales order

fulfilment, to indicate the second stage of an order when 'Order Pick&Pack'

is enabled

Item and debtor settings

Whether to apply the two-stage picking process can be configured per item

and/or per debtor. The most restrictive setting is always applied. When a debtor

is set to 'Allowed' or 'Mandatory', and one item to 'Not allowed', then that one

item for that debtor will not be 'packed'.

In item maintenance, for instance menu WMS, Setup Items, 'WMS' button,

the setting 'Order pick & pack' can be configured, and the same can be

configured per customer.

The default setting is empty (for existing items), which means the same as 'allowed'.

- Allowed: the picked line can be transferred to the packing

location, but can also be processed as picked from the picking locations

- Mandatory: it is mandatory to transfer the picked order line to

the packing location, process from stage 1 will result in an error

- Not allowed: the picked line cannot be transferred, and can only

be processed from stage 1

Sample scenario

An order contains 3 items, the order is to be picked in two stages for 2

items, and one item (1000C3) is not be transferred to the packing location.

The setting 'Order pick & pack' for the debtor and items 1000C1/1000C2 is set

to 'Allowed', but in item maintenance of 1000C3 'Order pick & pack' is set to

'Not allowed'.

In WMS control center Sales order fulfilment, the order is advised, send

picking, read back and validated. Buttons Process and Transfer are now

available.

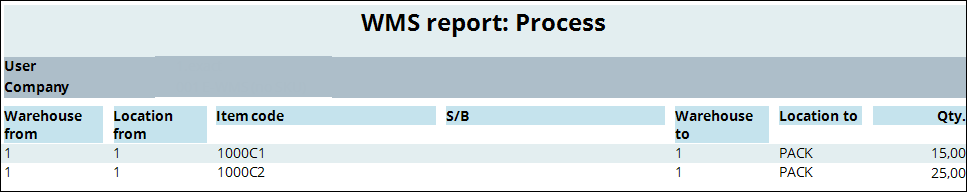

After pressing 'Transfer', items 1000C1 and 1000C2 are transferred to the

general packing location:

and part of the order is now sent back to status 'Advice', to be scanned from

location 'PACK'.

The two lines in status 'Advice' are now again sent picking, picked (now

using order 'packing'), read back and validated, and can be processed by

selecting both lines and using the 'Process' button.

Points of attention

- When rolling back an order while lines are already transferred,

the status 'Transferred' will be reset to 'No'. You will have to transfer items

back physically from the packing location to the warehouse.

- The transfers generated in control center Sales order fulfilment are

not handled by the WMS Transfers RF service, but are processed

manually in control center Sales order fulfilment, or by the WMS fulfilment

RF service (as transfers).

- When allowing for automatic validation and processing of transfers for

sales orders (either through manual read back or by the Fulfilment RF

service), then items or debtors configured as 'Allowed' or 'Mandatory' are

transferred to the packing location. When Pick&Pack type='Order' then these

lines are also put to status 'Advice' for round two of the process.

- Lines that are transferred at the end of stage 1 and are pending in

status 'advice', have to be sent picking manually. The Autoqueue service

does currently not put these lines from 'advice' to 'picking'.

- You cannot use 'immediate processing' or 'automatic fulfilment' in combination with Pick&Pack

type 'Order' or 'Transfers'. The WMS fulfilment RF service will read back and validate picked

orders, and can process the transfers to the packing location.

Processing orders and printing delivery notes has to be done manually in

control center Sales order fulfilment. Automatic processing (delivery note)

of sales order would also functionally not be logic for this type or order

process.

- Using 'multi-layer' (generated) SSCC registration cannot be practically

combined with Order Pick&Pack, since then you would have to generate and

print SSCC labels in both picking stages.

- Scanned SSCC registration could be combined with Order Pick&Pack, but

only when leaving the SSCC numbers empty in the first stage, and scanning

the SSCC numbers in the second stage.

This means you will have to configure SSCC registration to be 'optional',

since

SSCC numbers scanned in the first picking stage are not copied or made

available to the second order packing stage.

- Sales orders in the control center are shown split per 'transferred'

status. If part of a sales order is to be 'packed'

in stage two, and another part of the order is not, then you will see split

lines for this order (as shown in the screenshot above).

- When one order has both 'transferred' and not transferred lines (order

is shown split in the control center), then selecting one of these to process,

will process the whole order.

- Cost items (non-stock items; where GL stock account is not a balance account)

are not actually transferred, but regarded as 'transferred', when the real

item transfer is processed (from 413SP8/414SP2).

- When the scan unit is 'Sales unit' before the transfer is processed,

then the SKU number will be removed from the transferred picked lines. This

will be the case when combining E-WMS 'advice

collection' with Order Pick&Pack, or when picking part of a SKU. The

processed transfer lines are however linked to the sales order number by the

field CSPickITTransfers.SalesOrdernumber, for custom reporting purposes. The

transfer issue lines will show the SKU number.

Trouble shooting

- An order line is not transferred after read-back and remains with the

original picking location in status 'Validated', while the settings allow

for automatic processing of the transfer.

- The item is a cost item (G/L account is not a stock balance

account); or

- the item WMS setting 'Order Pick&Pack' is set to 'Not allowed'; or

- the debtor WMS setting 'Order Pick&Pack' is set to 'Not allowed'

- The WMS sales order fulfillment setting 'Stock transfers: immediate

processing' is not available.

- Pick&Pack setting 'Replenishment order' is not enabled (Pick&Pack is

disabled); or

- Pick&Pack type is set to 'bulk'; or

- Pick&Pack type is set to 'order', but WMS Fulfillment Advice setting

'Picking advice' is not enabled

Related documents