E-WMS - Collect advice per item

WMS documentation

Introduction

This document describes the functionality of 'Collect advice per item', as

available in E-WMS per release 410.

Description

This document contains following sections:

- General description

- Functional application

- Prerequisites

- Rules and limitations

- Settings

-

Sample scenarios

General description

In release 410, E-WMS introduces 'collect advice per item', where item

quantities can be summarized per order or over several orders, to be picked as

one total.

E-WMS already offered an option to 'collect' orders (in 'Send to scanner'

settings), but that type of collection does not summarize quantities for the

same item. Instead, several orders are presented in one virtual order on the

scanner, so when visiting a warehouse location, items for all orders can be

picked at the same time. This old method of collection can still be used in

combination with the new 'collect advice per item'.

'Collect advice per item' offers following advantages:

- more efficient order picking: pick 1x100 instead of 10x10

- since this collection is done before generating the picking advice, the

location advice will be optimized for these collected quantities

- a SKU advice can now be: pick 1 full SKU of 100, instead of picking 10 x

10 units from one or more SKUs

Functional application

You can benefit from advice collection, when you encounter one or more of

following scenarios:

- you allocated sales order lines to free stock, or to purchase orders or

production orders, resulting in split sales order lines. Without collection,

these split lines are offered on the scanner to be picked separately, but it

is much more efficient to pick this item as one total.

- due to the same reason (split lines due to allocation in Exact Globe

Next), the SKU picking advice is divided into partial picks from several

SKUs, while it would be possible and much more efficient to pick a single

full SKU.

- the sales orders from your customer are imported as Exact Globe Next

sales orders, where the process of your customer results in the same item

being ordered multiple times in the same sales order, but you want to pick

this as one total quantity per item

- you have several sales orders for different delivery debtors (or

addresses) of the same order debtor, but these orders are to be shipped from

your warehouse as a single shipment to a distribution node of your customer.

You want to pick these orders as 'collected' as possible.

- You regularly have backorders for specific items, and these items are

ordered later again additionally by the same debtor. Using advice

collection, these items can be picked as one total for all sales orders for

that customer.

Prerequisites

To be able to work with advice collection, following is required:

- License SE1380 E-WMS I

- Communication method 'ASP'

- Fulfilment setting 'Picking advice' is enabled

- Fulfilment Advice settings 'Allow partial delivery' and 'Allow partial

delivery of line' must be enabled

- Sales order 'partial delivery' is allowed (when collecting over multiple

orders)

Rules and conditions

These are the rules and conditions when working with 'advice collection'.

- Advice collection cannot be combined with 'Real-time replenishment' or

with 'Bulk Pick&Pack', due to the different advice logic in Advice

collection.

- Setting 'Scenario' in WMS Sales order fulfilment settings is not set to

scenario 1 ('Real-time Replenishment')

- Setting 'Pick and pack: Type' in WMS Sales order fulfilment settings is

not set to 'Bulk', while setting 'Replenishment order' is enabled

- In addition to the

configured collection criteria, item quantities are still always split

(not collected) per

different:

- order line warehouse code

- order line instruction text (only when WMS setting 'Send to

scanner/Instruction lines' is enabled)

- has Exact Globe Next allocations (yes or no)

- has WMS allocations (yes or no)

- recipe ID (for materials of an explode/make item)

- 'Explode - fulfilment' items are supported, however materials of an

explode item are always collected by 'recipe ID' (so by make item). If

a material is used in two different make items and the orders for these make

items are collected, then these materials are picked separately.

- Order lines containing items where the WMS item setting 'Order

picking' is set to other than 'Default, send picking' are not collected

but sent separately to be picked. This includes 'indirect' items like

materials for an explode item. When collecting 'explode items', it would be

best practice to set 'Order picking' to 'Default, send picking' for the make

item and all materials to be picked.

- Sales orders not allowing partial delivery, are not collected when

advice collection is set to 'Multiple selection'. Collection 'per order' is

however possible.

- Sales orders for which a

cross dock picking advice is generated, are excluded from advice

collection.

- In status 'Advice', 'Advice error' and 'Picking',

collected orders are visible as one order (one line in control center), showing

the order number of the first selected order when 'advice' was started, and a collection number as identification

- When the advice setting 'Advice collection' is enabled, all advised

sales orders are indicated as 'collected' in the control center and on scanner, even

when there is only 1 sales order in that collection

- When generating an advice, orders are never added to an existing

collection. If you want to add additional orders to an existing collection,

you have to rollback the existing collection and generate a new advice for

all orders selected together.

- When picking a collected order on the scanner, the real order number is

not visible since the quantity picked is the total for several orders.

Instead the first selected order number (when creating the advice) is shown.

- Rolling back a collected order always roll back

all single order parts of this collection

- On read back of the picked order, the collected order is split again

back to the original sales orders

- On read back of picked SKUs, scanunit will change from 'outer SKU' (or

'Inner SKU') to 'Sales units', because parts of the SKU will be assigned to

different order lines. When also using Pick&Pack 'Order' or 'Transfer', a

transfer is next generated from the picked (part of the) SKU. Because the

scanunit is 'sales unit' at that time, as a consequence the SKU number is

removed from the transferred order line.

This means when you are using 'Advice collection' in combination with

'Pick&Pack' type 'Order' or 'Transfer', the SKU numbers will be removed for

the picked lines, after the transfer is processed.

- When picking less than advised, on reading back the picked quantities

will first be assigned by allocation (S/B in

order line, WMS Allocations), then by sales order 'urgency', then by oldest planned delivery date.

- When 'freight data' (packages and weight) was entered on the scanner for

a collected order, this freight data will be updated with these entered

numbers to all sales orders within the picked collected order.

Changes

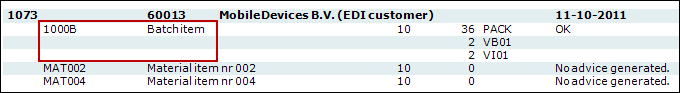

Following visible functional changes have been made related to 'advice collection'.

- New setting: Fulfilment advice setting 'Collect

advice per item'. Please read the linked document for details.

With this setting, collection is enabled, per order or over several orders.

- Control center Sales order fulfilment will show a new column 'Collection

no.' (collection number) when 'advice collection' (multiple selection) is enabled.

- The fulfilment advice report has been modified.

Sample scenario 3 shows a sample of the advice report when using advice

collection.

- In general the report has been changed technically, to support showing

collected advices

- When advice collection

is enabled, collected orders are shown grouped by collection number, showing

the ordered items per order, and one total advice for the total of these

quantities. This 'collected' part is ordered by item code.

- Collected orders consisting of just one order, are still shown as before

without collection number, but without order line numbers since the advice

can be a total for multiple order lines

- One order number could be part of more than one collection, due to

differences within the order lines (allocations, instruction text), or

generating advices on different times

- When part of an order is advised and collected, and another part is not

advised due to insufficient stock or other reasons, then the part not

advised is shown separately in the report, since it is not part of the

collection.

- Repeated line numbers, item codes and item descriptions are now

suppressed, when the

picking advice is divided over more than one warehouse location:

Technical changes

- Existing table csPickitOrsrgEx is used to contain collected advice records

(next to 'additional' picked items), in

combination with new table csPickitPreCollection.

- When 'Advice collection' is set to 'Multiple selection' then for order

lines in status Advice (status code 1), field orsrg.csPickitState is not yet

updated (is still status code 0 or NULL). Instead, order lines are blocked

in Exact Globe Next order entry by additionally checking for existence of

collection records in table csPickitOrsrgEx (orsrg.CSPickITOrsrgExGUID =

csPickitOrsrgEx.sysguid). From status 'picking' (status code 3),

orsrg.csPickitState is updated as usual.

- The advice report WMSFulfillmentAdvice.rpt has been changed and is also

using new SQL view exeaOrsrgAdviceView.

Sample scenarios

This document contains sample scenarios.

Related documents

| Main Category: |

Support Product Know How |

Document Type: |

Support - On-line help |

| Category: |

On-line help files |

Security level: |

All - 0 |

| Sub category: |

Details |

Document ID: |

26.485.452 |

| Assortment: |

E-WMS

|

Date: |

10-08-2017 |

| Release: |

|

Attachment: |

|

| Disclaimer |

|

|