Introduction

This document describes the SKU receipt process in E-WMS when SKU Management

is enabled. The details are based on product update 405.

Description

After SKU Management has been properly

set up, and SKU types and items have been

configured, you can start receiving SKUs in WMS Receipts Registration.

After creating and processing (printing) a purchase order for one or more SKU

items, you can start the E-WMS Control Center to handle the receipts.

This

document contains following process steps:

This document gives a schematic and visual presentation of the 'flow' for

E-WMS SKU receipts.

Control Center status 'new'

Start the Control Center Receipts in menu WMS, To be processed, Purchase

Receipts, Control Center.

Select one or more purchase orders to be received, and press the button

Send to scanner.

Depending on your settings you can encounter the windows:

Filter order lines, Send to scanner (communication type) and

Scanner (group) selection.

After sending, the selected lines will have status 'picking' in the Control

Center.

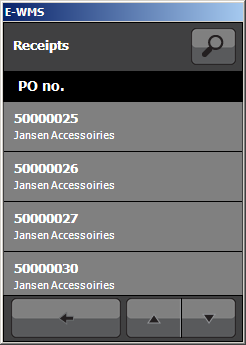

Receiving on the hand terminal

On the hand terminal, select menu 2 - Receipts and 1 - Receipts

and select (or scan) the purchase order to be received.

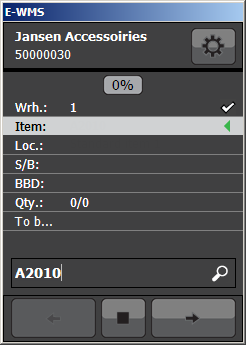

After selecting the purchase order, you may see a list of order lines,

depending on your settings. If not, you can enter or scan the item code:

Printing SKU labels

After entry of the item code, WMS will check if this is a SKU

item.

SKU labels can be printed using the SKU label printing screen. Whether the

SKU label printing screen appears automatically depends on the setting

Auto. SKU label screen.

Please note: when you have configured your hand terminal settings to prefill

and hide the receipt location, then the focus will immediately go to 'quantity'

after scanning the item code.

You would then, from the quantity field, have to press OPTIONS and SKU, to print

SKU labels; but the SKU number has to be scanned before entry of

quantity.

To avoid this scenario, please enable the hand terminal setting 'Auto. SKU label

screen', then the SKU print screen is automatically shown after scanning the

item code.

E-WMS remembers whether you printed labels earlier, for a specific item in a

specific order. When labels were printed earlier, then the SKU label screen

would not show but a SKU number can still be scanned.

If the label print screen does not show automatically, or you need additional

labels, you can press press the

OPTIONS button and choose the SKU menu button to start the SKU label screen

(in IE/ERF client: button

).

).

If more than one SKU configuration is found, you will see a list of available

SKU configurations in the SKU label screen. If only one configuration exists, it

will be selected automatically. Please select the appropriate SKU configuration.

The number of ordered sales units from the order line will show as suggestion to

print labels for:

The following information is displayed:

| Item |

Item code |

| Qty to label |

The expected quantity in sales units to be received |

| Out.SKUType |

The selected SKU type code |

| Out.SKUDescr |

Description for this SKU type |

| Qty.outerSKU |

Number of sales units per SKU type |

| Out.SKU Lbls |

Number of labels to print

(sales units / sales units per SKU) |

If you receive less or more sales units (as a total for this receipt, not

per SKU), please change the total quantity accordingly.

From the entered quantity, the number of labels (SKUs) will be calculated,

rounded up, in case of a last incomplete SKU.

In this sample, labels for 5 pallets are now to be printed:

After confirming the number of SKU labels, the printing will be done

automatically by BarTender Commander, when properly

configured.

These labels must be applied to the received SKUs (pallets or boxes), so scanning and

registration of the SKU numbers can start.

From

product update 405 it is possible to scan 'external' SSCC numbers as SKU

number. Otherwise only numbers generated by E-WMS are accepted as valid SKU numbers.

Receipt

Now the actual receipt can start:

- scan location (when not prefilled and skipped)

- scan the SKU number. You can scan the same SKU number more than

one time, as long as that SKU number was already part of the same receipt

transaction.

You can only use one item (and one batch) per SKU number.

- if the item is a batch item: scan batch

- in input of batch start/end date is required: scan dates

- quantity in sales units for this SKU, will be prefilled

with the standard quantity configured for this SKU type.

When receiving a batch item, the batch will have to be scanned after scanning

the SKU number. At the moment, you can only use one batch per SKU but this is

not validated in the ASP receipt process.

When receiving a serial number item you will scan a serial number multiple

times, after scanning the SKU number, until the SKU quantity is reached or your

press the STOP button.

Now the next SKU is expected, with again (batch and) quantity, until the

ordered quantity is reached, or until you press the STOP button (or in IE/ERF

client: one of the buttons

LINE READY or READY).

Reading back and processing

The picked lines which are 'ready' on the hand terminal, can be read back in

the Control Center Receipts, after selecting Picking at the Status field, or can be read back

automatically when the RF Receipts service is up and running.

Depending on your settings, the receipts can be validated and processed

automatically after reading back. When these steps are not started

automatically, it is possible to open a receipt and show the SKU receipt lines.

The SKU numbers can be changed, and are still validated when doing so (so

they have to exist).

After processing, the Exact Globe Next shelf stock is updated with the total quantity

received. SKU details are only visible in WMS reporting tools, as there are:

- WMS, Reports, Item/Stock view (SKU stock details per item

including E-WMS stock reservations)

- WMS, Reports, SKU transaction history (SKU transaction details)

- WMS, Reports, SKU stock (SKU shelf stock positions)

The next step would be to

transfer these SKUs from the receipt location to warehouse bulk locations.

Related documents