E-WMS - Pivot Point ('Manual input qty above')

Introduction

This document describes the functionality of Pivot point or 'manual input quantity' (Dutch: 'omslagpunt').

Description

Pivot point is intended to make the scanning process faster when you scan smaller quantities, or to be very precise on the quantity of the items.

When enabled, the manual input of quantity is skipped and scanning 1 item barcode means '1 picked'.

Pivot point can be enabled in the scanner settings in Exact Globe menu System, E-WMS, Scanners for the following processes:

- Sales Order Fulfillment

- Receipts

- Replenishment

- Production Issues

Rules

- The Pivot Point quantity (the point where Pivot Point is enabled or not) is based on the original quantity to pick per

advice line, so is not dynamic during picking.

In the

sample

scenario below, the

Pivot Point for item2 will still not be activated after fulfilling quantity 2 of total 12 (and theoretically reaching pivot point '10')

- When using Route Optimizing the order line may be split in separate picking lines (because of batches and locations).

Pivot Point is based on the quantity per single advice line, not on the quantity in the order line.

- When using

WMS scan codes

with alternate factors, the scan code factor is applied when using

Pivot Point and scanning a scan code

- When using pivot point with batch items, the 'pivot point' is still

based on the item code. This means your scan flow in order picking (and when

quantity 5 to pick) would be:

location - item - item - item - item - item - batch

- Pivot Point is not intended to work with 'divisible' items (quantities with decimals).

Pivot Point will be automatically disabled when picking a divisible item.

- Pivot Point does not support scanning of composite barcodes

(GS1-128/HIBC) or using WMS 'scanning

combination'. When these are used, the pivot point flow will be

interrupted, and behavior will be as when scanning the barcode without pivot

point enabled.

- Pivot Point is not intended to work with GS1-128/HIBC barcodes with also contain a quantity. In that case, using

Pivot Point would not even be necessary.

When scanning such a bar code,

Pivot Point will be disabled and return to normal flow.

- When using

Pivot Point on a ASP hand terminal, the transaction is not written to the RF tables until the whole line is picked or you indicated by pressing the Continue button that you want to scan

another item

- When the WMS Receipts setting 'Quantity: Purchase units' is enabled, then the configured pivot point quantity is matched

with the quantity in purchase units.

When this setting is disabled, the pivot point is based on the quantity in

sales units.

- If you want to pick less than advised using Pivot Point, you should use

the NEXT button:

This way, you can end this picking line the right way, and E-WMS will ask you if you want to close the line, or continue picking

this line later.

- When working with random item scanning and pivot point, like in

Receipts with setting 'Guided flow'='Random scan', you have to press

the 'NEXT' button

to indicate that you are done with the current item and want to

continue with a next (random) item.

to indicate that you are done with the current item and want to

continue with a next (random) item.

As long as ENTER is given after a scan (by the scanner or manual) then you

will add '1 scanned' to the current item, but that same item is also

expected again (item code is shown on next scanning screen).

So to be able to scan another item, you first have to press the 'Continue'

button.

The transaction is only written to the WMS RF tables when pressing the

Continue button.

- When using the E-WMS offline CAB client, pivot point only works in Sales

order fulfillment (and only setting 'Pivot point', not 'Pivot point batch')

- For scanner settings Sales order fulfillment and Receipts, Pivot Point

can be configured separately for standard items or batch items. For

Replenishment and Production Issues, there is one setting for both item

types.

Settings

The settings for Sales Order Fulfillment can be defined in menu System, E-WMS, Scanners, Sales Order Fulfillment.

Pivot Point quantity

Quantity 0 (zero): pivot point is disabled

Quantity 1 or higher: when the advised quantity for the line to be picked, is smaller or equal to this quantity, then input of quantity is skipped and each scan of the item = quantity 1 picked.

In Sales Order Fulfillment and Receipt settings, this setting is applied to standard (non batch) items only.

In Replenishment and Production Issues, this setting applies to standard and batch items.

When using the hand terminal CAB client, this setting is used both for

standard and batch items (Sales order fulfillment only).

Pivot Point batch

This setting is only available in Sales Order Fulfillment and Receipt

settings, and works the same as 'Manual input qty above', but is only applied

when scanning a batch item (ASP only).

Sample scenario

Sales Order Fulfillment pivot point is set to '10'.

The sales order has following order lines:

1. standard item 1 quantity 10

2. standard item 2 quantity 12

3. batch item 3 quantity 8

The order lines are sent to the hand terminal to be picked :

- When scanning item1, input of quantity is skipped. Each scan of 'item1' results in '1 picked'

- When scanning item2, the quantity has to be put in manually

- When scanning item3, input of quantity is skipped. Each scan of 'item2' results in '1 picked'

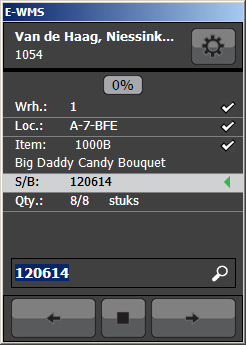

On the hand terminal, the first line for standard item 1 (1000G) is selected,

the location is scanned, and the first item code is scanned.

The screen remains at input of 'item code' and indicates that 1 out of 10 is

scanned, still 9 to scan. Each scan of the item code adds '1 picked'.

Five more items are scanned, but then it turns out that the remaining

expected stock is not available, so only 6 items can be fulfilled right now.

To continue with this line, you can now either press the NEXT button

or press the STOP button. Both buttons have the same effect at this point

when 'pivot point' is enabled, and will start the 'scanned less' dialogue. You

can now close this line (the remaining 4 will not be picked anymore), or answer

'No', in the latter case you will return to the start of the picking screen for

this item.

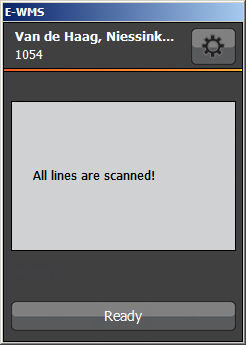

In this case, the line is closed and scanning continues for the batch item.

First the location is scanned, then the item code. After scanning the item 8

times in total, input of the batch number is required.

For the third item, the quantity to pick is 12, more than the pivot point

setting (10); so for this item the quantity just has to be entered:

Related documents

| Main Category: |

Attachments & notes |

Document Type: |

Support - On-line help |

| Category: |

|

Security level: |

All - 0 |

| Sub category: |

|

Document ID: |

19.915.628 |

| Assortment: |

E-WMS

|

Date: |

17-12-2020 |

| Release: |

|

Attachment: |

|

| Disclaimer |