Introduction

This documents describes the functionality of E-WMS Directed Put Away,

as per release 412.

Description

Directed Put Away (DPA) is introduced in product update 402 and offers

the possibility to get a calculated advice where stock can be stored in the

warehouse, in WMS transfers.

This document contains following sections:

Availability

DPA is available from product update 402, in WMS ASP transfers menu 'Transfer from'. From product update 405, the

maintenance screen for Location types changed to reflect the DPA logic.

Requirements

Following is required to use DPA:

- License E-Warehouse Location (SE1312)

- License E-WMS II (SE1381)

- or: Pick-IT Replenishment (SE5711), but then you cannot use SKU

Management

- Usage of E-WMS communication method 'Scanner - ASP'

- Configuration of WMS location types

Rules

Following rules are applied when working with DPA:

- DPA can be used for SKU and non-SKU items. When using SKU items,

dimensions can be used to calculate available space. For non-SKU items

('sales units' stock), only the maximum quantity per location can be used.

- Configuration of

location types

is mandatory for DPA; enable the location type option 'DPA target location' and link this location type to your locations

intended as DPA target location.

- For SKU DPA, dimensions must be configured. Enabling the location type

setting 'Dimensions: unlimited' is not specific, it states that anything

could be stored here.

- DPA will work only optimal for locations configured as 'variable item/batch/end

date' or 'fixed item' (bulk) locations. Locations allowing 'multiple item

codes' could be advised

but without stock or dimension checks, and are therefore not specific.

- Locations already having stock of a specific item and also having space for

additional stock, have no preference when calculating a DPA advice

for that item. This applies to DPA and Replenishment.

- The DPA location is not recalculated when you press the BACK button on

the hand terminal and changing for example 'item code' or 'quantity'. You have

to press STOP and return to input of 'item code' (or 'location').

- 'Unit type' in maintenance of Location Types, is to be considered as: unit

type per item. Using 'unit type=variable unit type' is applied as:

one specific SKU type for one specific item.

- Two different items can only be stored by DPA on one location, when

there is no restriction configured on 'variable' stock (item, batch or end

date) or on fixed- or variable unit type, or when a fixed SKU type is

configured without further restrictions. However, configuring a location

type as 'multiple items' is not very specific and will probably end up in all

transfers being advised there.

- DPA is possible within the same warehouse or between different

warehouses. When transferring from warehouse 1 to 2, the warehouse employee

just has to enter '2' as target warehouse, and location types have to be

linked to locations within warehouse 2. Then DPA can calculate a suitable

target location in warehouse 2.

- Usage of

items per location type or

WMS item locations is

technically not mandatory for DPA of sales units (no SKU); but when

doing so, you can define maximum quantities for the target locations which

will be required for practical use.

- Configuring 'items per location type' or 'item locations' for an item

does not limit the DPA advice to locations only linked to that item.

DPA will (at the moment) still advise all DPA locations for all items. DPA only uses

the configured maximum level from the item-location links. Limiting the DPA

advice to only the configured item-location combinations, may be a

future addition to DPA logic.

For the calculation of candidate target locations following rules are used:

- When scanning a receipt or transfer of a SKU: the availability of storage space (or dimension

calculation) on a location applies following rules:

- Dimensions of the location type

are compared versus dimensions of the SKU item configuration

- The location type setting 'Dimensions: unlimited' is not used for SKU

DPA based on dimensions. In that case, SKU quantities are compared

with location maximum quantities

- Dimensions will only be calculated when the location is linked to a

location type configured as 'Unit type'='Variable SKU/item

configuration' and when the location is in effect of type

'variable/fixed' item.

This is because dimensions are calculated based on the item/SKU

configuration to be transferred, so we can only assume that the same item is

already stored on that location (when location allows multiple SKUs). - 'Stackable' property of the location

(from 407)

- 'Stackable' property of the SKU item configuration (from

407)

- When a location does not allow 'stacking' but still offers room for more

than 1 SKU then the number of SKUs on that location are calculated, and

should at least allow room for 1 more SKU

- The current occupied stock on a location including non-processed WMS

receipts and transfers

- Next to total 'free space- and stock dimensions (cubic cm), also the

separate dimensions are compared: width, depth, height.

- Before release 407, this was only applied in DPA. From release 407,

this is also applied in all SKU receipt scan functions.

- When scanning sales units (SKU item as sales units, or

SKU without (valid) dimensions, or no SKU item), then the availability of storage space on a location is based on:

- maximum quantity defined in WMS Item Locations minus current shelf stock

and pending receipts

- or else: maximum quantity defined in WMS Location Types minus current shelf stock

and pending receipts

- the location must be a 'variable (or fixed) item' type location (either

through location- or location type settings)

- The 'current stock' on locations is not calculated and regarded as

'zero', when:

- the location type allows multiple items

- scanning a SKU and the location has no valid dimensions ('dimensions

unlimited' or one or more of the dimensions is 'zero')

This means that locations for which no dimensions are configured, or have

no variable-stock restrictions, always are advised

as DPA locations, which may not be desired at all.

Therefore it is prudent to only configure DPA location types with 'variable

item' restrictions.

- Scanned item code matches item code for 'fixed item' locations, or

location is not of type 'fixed item'

- Scanned item code matches item code of current stock on 'variable item' location, or location is not of type 'variable item' or location has no stock

- Scanned item code and batch codes matches item code and batch code of current stock on 'variable batch', or location is not of type 'variable item' or location has no stock

- End date of scanned batch and item code matches item code and end date of current stock on 'variable end date' location, or location is not of type 'variable end date' or location has no stock

- The scanned unit type matches the 'allowed stock unit' types of the location

- When scanning a SKU: scanned SKU item type matches current stock of 'variable SKU item type' location, or location is not of type 'variable SKU item type' or location has no stock

- When scanning a broken or incomplete SKU: the location type setting to allow 'incomplete SKU' has to be enabled

- The scanned unit type matches the unit type of current stock at the location of type 'variable unit', or the location has no stock, or the location type allows 'multiple units' at the same time

The list of candidate target locations is sorted on location preference (defined in

Exact Globe Next warehouse locations maintenance) and then by location code alphabetically, the first location in that list is presented as advised location.

From release

408, it is possible to include

location distances in your DPA advice: store stock nearby the item main

location, or nearby the transfer source location. This policy affects the

sorting of the list with suitable locations, so a more logical (near by)

location would now be advised first.

Supported scenario's

Following properties of warehouse locations and WMS location types are

supported in E-WMS processes.

In DPA, there are two moments where location rules are applied:

1.

DPA prefills a calculated target location on the hand terminal

2. After confirming this location by scanning or pressing ENTER, WMS applies the

'receipt location validation'

on the scanned value

In Replenishment, there are several moments where location are (or can be)

applied:

1. In calculation of the requirements per location (what needs to be refilled)

2. In generation of the picking advice (what stock is picked to refill the

picking locations)

3. When opening a generated advice

4. When scanning the issue on the scanner (the receipt location is not

scanned in E-WMS Replenishment)

5. After reading back, in validation of the scanned lines

6. On processing the transfers, WMS and Exact Globe Next (SDK) validate the

transaction again

Properties (per release 407) |

DPA |

Replenishment

target location advice |

ASP receipt location

Scanned location validation *1 |

| |

|

|

|

|

|

|

|

|

| Warehouse Location properties |

|

|

|

|

|

|

|

|

| Variable item |

|

Yes |

|

Yes |

|

|

Yes |

|

| Fixed item |

|

Yes |

|

Yes |

|

|

Yes |

|

| |

|

|

|

|

|

|

|

|

| WMS Location Type properties |

|

|

|

|

|

|

|

|

| Variable stock: variable

item |

|

Yes |

|

Yes |

|

|

Yes |

|

| Variable stock: variable batch |

|

Yes |

|

No |

|

|

Yes |

|

| Variable stock: variable end date |

|

Yes |

|

No |

|

|

Yes |

|

| Allowed stock units:

sales

units/ outer/ inner/ incomplete SKU |

|

Yes |

|

No |

|

|

Yes |

|

| Unit type: multiple/variable/variable

SKU item |

|

Yes |

|

No |

|

|

Yes |

|

| Fixed SKU type |

|

Yes |

|

No |

|

|

Yes |

|

|

'Dimensions: unlimited' or 'maximum quantity' validation per location

*2 |

|

|

|

|

|

|

|

|

| - |

Maximum stock per location type per item

(items/location type) |

|

Yes |

|

Yes |

|

|

Yes |

|

| - |

Maximum stock per location per item

(items/location) |

|

Yes |

|

Yes |

|

|

Yes |

|

| SKU stackable |

|

Yes |

|

No, n/a |

|

|

Yes |

|

| Dimensions: height, width, depth |

|

Yes |

|

No, n/a |

|

|

Yes |

|

| |

|

|

|

|

|

|

|

|

| Other properties |

|

|

|

|

|

|

|

|

| First advice location which already

has same item

and room for more

|

|

No |

|

No |

|

|

n/a |

|

| Include unprocessed WMS receipts (or

transfers) in calculation |

|

Yes |

|

No |

|

|

Yes |

|

| Advice multiple locations for large transfer

(split) |

|

No |

|

Yes |

|

|

n/a |

|

| Advice 'best-fit' location for quantity to transfer |

|

No |

|

No |

|

|

n/a |

|

| Limit advice to only

locations linked to the item |

|

No |

|

Yes |

|

|

n/a |

|

| Regard

DPA location already as occupied after advising (before scan) |

|

Yes |

|

n/a |

|

|

n/a |

|

| |

|

|

|

|

|

|

|

|

*1: Except in scanner function 'Transfers/Transfer to one' or

'Transfers/Repack to'; then no validation is done for the target location,

because then multiple stock positions can be transferred at once

*2: Applies to 'sales units' (no SKU stock) only

Configuration

General settings

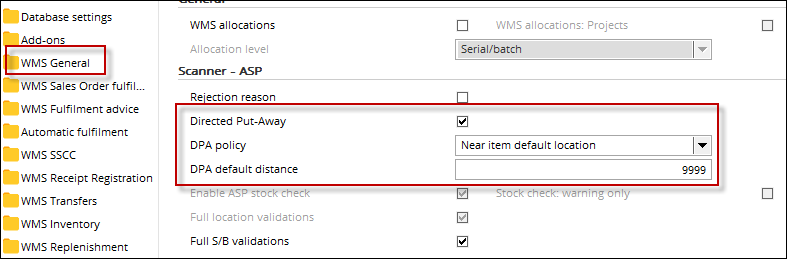

DPA is by default disabled and has to be enabled in Exact Globe Next menu System, General, Settings, WMS General, section

Scanner - ASP, setting Directed Put Away:

You can read more about these DPA settings in document

E-WMS - General settings.

DPA policy - 'near' a location

Optionally you can influence the sort order of the list of all suitable

DPA locations, to locations near the item default location, or near the transfer

source location.

Default, the list of DPA locations will be sorted by 'preference' (as

configured in location maintenance,

WMS button), then alphabetically by location code.

By applying a specific DPA policy (see 'General settings' section above) you

can change that sort order, to:

- distance between item default location and suitable DPA locations, then

'preference', then alphabetical ; or :

- distance between the transfer source location (like 'receiving dock')

and suitable DPA locations, then 'preference', then alphabetical

The lower a distance, the higher the preference as DPA target location. This

way you can configure more item-specific DPA locations, provided the item

default location can be configured for this purpose.

This means you have to configure (low)

distances between the item default location and all possible DPA target

locations for this item. For any DPA location not configured, the default

distance of 9999 will be applied.

Please note that still, when all these preferred locations would be 'full', any

other DPA location can be advised.

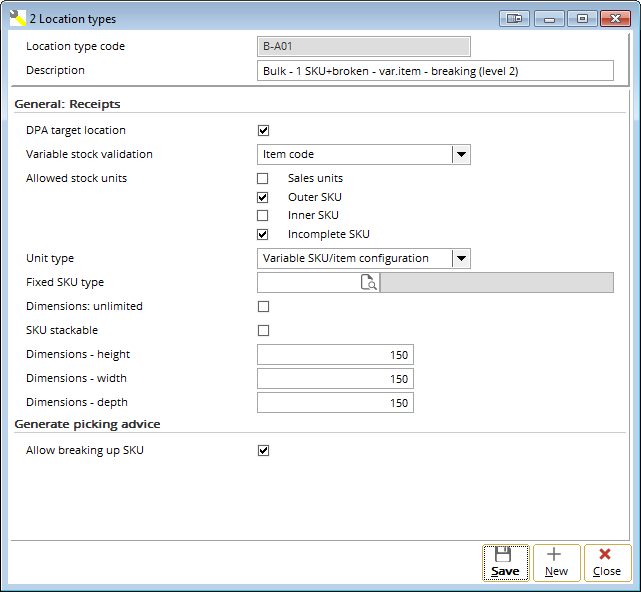

Configure locations as DPA locations

Default no location is used as DPA target location. You will have to

configure WMS Location Types in menu WMS, Setup,

Location management, Location Types, Location Types and enable the option 'DPA target location' for location types intended as DPA targets:

After this, locations have to be linked to location types, using the

WMS button in location maintenance.

Using DPA without SKU

It is possible to use DPA without using SKU Management, but you do need

license module SE1381 E-WMS II. In that case, the location advice is based on

the configured maximum quantity per location.

This means you need to configure these maximum levels either in WMS 'items

per location type', or in 'WMS item locations'. These configurations are primary

intended for WMS Replenishment but are also used for WMS DPA.

'Item locations' have higher priority than 'items per location type', so you

can configure 'Items per location type', with exceptions in 'Item locations'.

Usage

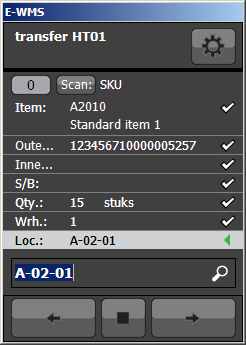

The application of DPA is very simple and straight forward; when enabled, and DPA found a suitable location, the 'target location' field is prefilled with the advised location.

For example, transferring a SKU, location A-02-01 is advised.

Related documents