Introduction

This document describes the configuration and working of E-WMS Autopack

and SSCC Shipment Builder in Exact Globe Next, per product update 409.

Description

This document contains the following sections:

Autopack can be used when you need shipment labels during your sales order fulfillment process, but

when you do not want to use order picking using scanners.

Autopack and SSCC Shipment Builder offer a shipment label print solution without the need to use

scanners. From product update 406, the Autopack and Shipment Builder functionality is

available as independent functionality in Exact Globe Next menu Order, Entry,

SSCC Shipment Builder. When using SSCC Shipment Builder, other menu

paths apply than used for E-WMS.

From product update 407, serial/batch items are also supported in this process.

E-WMS Autopack or SSCC Shipment Builder will offer following functionality:

- configure items as 'WMS Autopack' item

- configure standard shipping units (WMS 'SKU types' is used) such as pallets or boxes, per

item

- buttons 'Autopack' and 'Shipment builder' in menu

WMS, To be processed, Order fulfillment, Control Center (or:

Order, Entry, SSCC Shipment Builder) provide Autopack advice

functionality and Shipment Builder functionality

- selecting one or more sales orders to be shipped in one shipment, with

automatic assignment of shipment number to the selected sales orders

- automatic creation of shipment structure: divide ordered quantities into in boxes and pallets

with automatically assigned unique SSCC numbers

- change shipment structure: create new pallets or boxes, move order

quantities between boxes and pallets

- label printing: printing shipment labels based on your SKU configuration

in the Shipment Builder, up to 3 different label types (inner SSCC/box, outer

SSCC/pallet, shipment)

- the SSCC numbers generated and printed by E-WMS or SSCC Shipment Builder are stored and can be used

for the Exact E-EDI delivery note message.

Following terms are used in Autopack:

- SKU: Stock Keeping Unit; a unit which holds one or more standard

sales units of an item. In this document this refers to the 'SSCC' unit,

being a pallet or a box. 'SKU' is the internal stock unit when using E-WMS

SKU Management, 'SSCC' is the shipping stock unit.

- SSCC: Serial Shipping Container Code, a

standard set by GS1, an 18-digit unique digit code used to identify

SKUs or shipping units in logistical processes

and in EDI messages between trade partners.

- The SSCC number is

build up as following:

- position 1: Extension digit, free assignable by the party that creates

the SSCC, can be for example a reference to a specific plant or branch of

your company

- position 2 to 17: the GS1 company prefix (in most cases 5 or 7

digits), followed by a sequence number,

making this SSCC number globally unique

- position 18: computed control digit (modulo 10 method)

- The GS1-128 (EAN128) application identifier '00' is added as prefix to the SSCC number in

GS1-128 bar codes, but is not part of the SSCC number itself - just of the

barcode

- Outer SSCC: a unit which is commonly also the transport unit, like a

pallet, and may contain several inner SSCC's

- Inner SSCC: a unit which is commonly used to build an outer SKU,

for example a box or a case

- GS1: an

international

organization dedicated to the standardization in the national and

international demand- and supply chain. GS1 regulates for instance the

standards of bar coding. GS1 was formerly known as 'EAN International' or 'Stichting

EAN' (Netherlands).

Prerequisites

Following is required to use WMS Autopack or SSCC Shipment Builder:

License requirements

- One of following Exact Globe Next modules:

- SE1380 E-WMS I (or older license SE5700 Pick-IT)

- SE1386 E-WMS Lite

- SE1387 SSCC Shipment Builder (available from product update 406)

- BarTender labeling software.

The 'BarTender

Automation' edition would be sufficient, when used only for this purpose

and when printing labels directly from the workstation.

When you plan to use E-WMS hand terminals and print labels from hand

terminals in the future, it may be better to purchase the 'BarTender

Enterprise Automation' edition.

See

WMS system requirements

for more details.

Practical requirements

- Bartender needs to be installed on any workstation where labels are

printed (where the control center will be started), or the BarTender

'server' method can to be used (requires other BarTender edition).

- The label printer has to be supported by BarTender (see

printer list of Seagull Scientific)

- Use the printer drivers provided by Seagull Scientific, experience has

shown that these can perform much better

- You need labels, check if your

labels would have to support specific environmental requirements (cold storage requires other quality labels)

- BarTender label layouts based on SQL views. Consultancy may be

required,

sample labels are available

- When not using the BarTender

'server' method:

- label layouts are linked to one specific Exact Globe Next company.

When using Autopack in two or more companies, you need to create copies of the

BarTender lay-outs and manage these separately.

- The views used in the BarTender labels need to be created in each Exact

Globe Next company (SQL database) used for SSCC Shipment Builder.

Rules and restrictions

- From product update 407, Autopack can be used for batch items or serial number items.

In release 406 and earlier, serial/batch items are not supported

- Autopack will only use the default location of an item, therefore

sufficient stock on this location is required (when using locations), also

for serial/batch stock

- SKU stock is not supported in Autopack/Shipment Builder

- Autopack cannot be used in combination with order picking on E-WMS hand

terminals

- When an Autopack advice is generated for serial/batch items,

serial/batch numbers will be automatically assigned to SSCC number, starting

with the lowest S/B numbers in the lowest SSCC numbers

- Items to be used in Autopack must be configured as an 'WMS Autopack' item

(E-WMS setting in

item maintenance)

- The WMS settings 'Multi layer SSCC' and 'Autopack' must be enabled in

WMS SSCC settings, to enable the Autopack functionality

In a SSCC Shipment Builder license (SE1387), these settings are enabled by default,

and not visible.

- The shipment number is assigned when selecting one or more sales orders

to be 'auto packed', and can not be changed afterwards

- It is not possible to include these SSCC numbers on the Exact

Globe Next delivery note layout, as mentioned in document 'WMS

known issues'. Instead, the 'processing report' could be changed to act

as 'SSCC attachment'.

- Exact Globe Next enrichment is not supported. Enriched order lines

cannot successfully be processed in the Control Center.

- You cannot use external or existing SSCC numbers with Autopack

functionality. Autopack will always generate new SSCC numbers, based on the SSCC

number settings.

Installation

Exact Globe Next and BarTender

When downloading and installing Exact Globe Next, all required parts are

available, except for BarTender. BarTender is not part of Exact and needs to

be purchased and installed separately, and consists of a license service (to be installed

once) and the client installations for designing and printing. A BarTender trial

version can be downloaded from

Seagull Scientific,

but using a trial version of BarTender is not supported (though it may work).

When using the BarTender

'server' method, this document applies: setting up hand terminal label

printing

BarTender labels

You can configure up to 3 different labels: one for inner SSCC's (cases), one for

outer SSCC's (pallets), and one for the shipment. Designing these labels with bar codes and

texts is not part of this document, but sample labels and SQL views are provided

in document

BarTender - WMS integration: mandatory fields and samples.

You can use these views and labels to get started. Please remember to

change in

each label lay-out file: server name, database name, SQL login and printer; since these labels are

build with a default configuration. In you are using these labels in a network

environment, you may save the labels in a shared folder. Following sample

lay-outs are provided: eWMSAutopackBox.btw, eWMSAutopackPallet.btw and

eWMSAutopackShipment.btw.

SQL views

When using the BarTender 'client' method (default method for these SSCC

labels), then the label lay-outs are based on SQL views. Some field names in these views are

mandatory, besides that, you are free to add any fields you need. To access the

data in the BarTender labels, you may configure a dedicated SQL user. That way,

you do not need to grant rights to each user printing these labels.

Following sample SQL views are provided: eWMSAutopackBox.sql,

eWMSAutopackPallet.sql and eWMSAutopackShipment.sql.

Setting up labels in WMS

The labels created in step BarTender labels need to

be linked in Exact Globe Next menu System, E-WMS, Labels,

for each of the label type you want to use. If you are using labels for each

box, pallet and also separate shipment labels you will need to configure all

three labels here. If you are using only pallet labels, you only need to

configure one label, linked to 'application': "SSCC - Autopack: Pallet". It is

possible to configure multiple label lay-outs (with each also possibly a

different SQL view) for the same 'application' step, these will all be printed

subsequently.

Please see document

E-WMS menu: System, E-WMS, Labels for details on how to create a label

configuration.

CONFIGURATION

General Autopack settings

Autopack is enabled in Exact Globe Next menu System, General, Settings, WMS SSCC.

Please see document

E-WMS settings: WMS SSCC for more details.

The following settings have to be changed:

- SSCC numbers: enabled

- Use multi-layer SSCC: enabled

- Number settings configured to generate SSCC numbers

- Use Autopack: enabled

Configure items for Autopack

There are three important factors for an Autopack item:

- 'Use AutoPack' must be enabled

- Only from release 407, serial- and batch item are supported.

Earlier releases did not include automatic assigning of serial- or batch numbers

into box- and pallet SSCC numbers.

- the item must have a valid GTIN/EAN13 number (14 digits) when you want

to print valid UCC/EAN128 bar codes (may also require changing the SQL

views). The views will default assume that the item/supplier field 'ean

code' contains a 14 digit GTIN/EAN code which can be included in the SSCC

labels.

- a default warehouse location must be configured for the item in the used

warehouse, and that location must have sufficient stock (when you are using

warehouse locations in Exact Globe Next)

- SKU stock is not supported in Autopack

An item must be enabled as 'Autopack' item before it can be used in Autopack.

Use the WMS button in item maintenance, for instance in Exact Globe

Next menu Order, Items,

Maintain.

When sending sales order lines to be auto packed, the quantities will be

fulfilled from the item's default location in the shipping warehouse;

Therefore it is necessary to have sufficient free stock available on this

default location, before starting Autopack.

Configure SSCC types

Exact Globe Next menu WMS, Setup, SKU, SKU

types

allows you to configure your basic SSCC types = pallets or cases, or other

logistical units.

In SSCC Shipment Builder license (SE1387), this is menu

System, E-WMS, SKU types.

These SKU types will be linked to your Autopack item in the next step.

Press New to create a new SKU type:

SKU type

Assign a code to this SKU type (10 characters, alphanumerical)

Description

Give the SKU type a clear description (pallet- or

box type).

Note: when changing the description of an existing SKU type, this change will

not be replicated to already existing 'SKU configurations per item'.

Inner SKU

Enable this setting if this packaging type can be part of an outer SKU, so in

case of boxes for example.

Dimensions (height, width and depth)

Dimensions are used in

WMS SKU Management

but not in Autopack. These can be filled for your own information but are

not required for Autopack.

Configuring SKU per item

Exact Globe Next menu WMS, Setup, SKU, SKU per item

(or in a SSCC Shipment Builder (SE1387) license: menu System, E-WMS, SKU per item)

allows you to configure the structure of an item; how many sales units

are in a box, and how many boxes are on a pallet. Based on this structure linked

to your item, SSCC numbers (box and pallet numbers) are automatically generated

when starting 'Autopack' for a selection of sales orders. One item can only have

one active Autopack configuration. A configuration can be just an inner SKU, just an

outer SKU, or a combination of both.

Please see document

maintenance of SKU per item for more details.

USING AUTOPACK

Start Autopack

Create one or more sales orders with 'Autopack enabled' items. Authorize and

confirm these orders when required.

For E-WMS or E-WMS Lite, start Exact Globe Next menu

WMS, To be processed, Order

fulfillment, Control Center.

For SSCC Shipment Builder SE1387, start Exact Globe Next menu

Order, Entry, SSCC Shipment Builder.

Because Autopack is enabled, this Control Center now shows:

- a new column Shipment, which will be filled with a unique

shipment SSCC number when the Autopack button is used,

- button AutoPack, to generate the shipment structure and SSCC numbers for the selected sales

orders, and

- button Shipment builder, which will become active after Autopack

has been started.

To combine several orders in one shipment, you can select these orders using CTRL- or

SHIFT when selecting the orders and then press AutoPack.

A report will show when the Autopack report setting was enabled.

In release 406 or earlier, this is a basic report showing only the status

'Autopack generated' per order. From release 407, the report shows the shipment

structure on SSCC and item or serial/batch level. You can read more about

this report in

this document.

After this step, the items have been 'adviced' from their default locations, and

Autopack automatically generated SSCC numbers for inner and outer SSCC's, based on the SKU

configuration for each item.

Also a shipment number has now been assigned to the selected sales order lines.

All selected orders have the same shipment number.

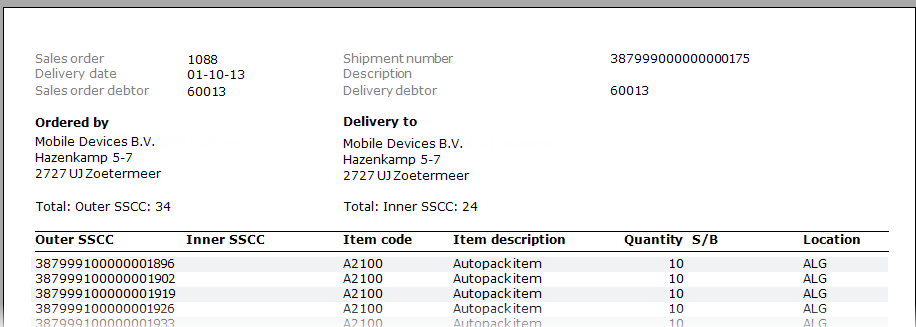

Shipment Builder - editing a shipment

The Shipment Builder will now open automatically showing the generated

shipping configuration as a tree structure.

The quantities from the sales order lines were automatically assigned to inner

and/or outer SSCC's.

In this sample, Item 1000K is stacked directly on a pallet (350 units per

pallet, 500 to be fulfilled).

Item 1000H is stored in cases of 4 sales units, with 25 cases on a pallet.

The shipment tree has following structure:

- Shipment SSCC number (811234100000000103)

- Outer SSCC number (811234300000000244, 811234300000000251,

811234300000000268)

- Inner SSCC number (when used; 811234500000000279,

811234500000000286)

Using the '+' and '-' indicators in the tree, you can expand or collapse a level.

You can still edit this default shipment structure, SSCC's can be removed or added,

and quantities can be 'dragged' to another SSCC or outside the shipment

structure.

You can use buttons New SSCC,

New Inner SSCC and

Delete to manage the shipment structure.

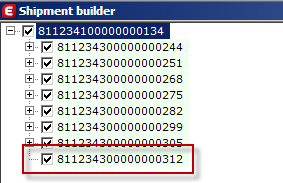

New SSCC

The button 'New SSCC' Generates a new outer SSCC number and adds this to the tree. This sample shows a collapsed tree structure,

showing only outer SSCC's (pallets), after pressing New SSCC a new pallet

number has been added:

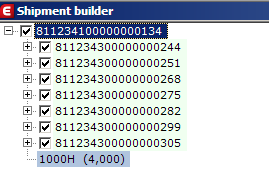

New inner SSCC

The button 'New inner SSCC' creates a new inner SSCC number and adds it to the tree.

When you selected the shipment number while pressing New Inner SSCC, the

new SSCC will be added to the bottom of the tree on 'outer SSCC' level. You will have to drag the new

inner SSCC to an outer SSCC ('place the box on a pallet').

When you selected an outer SSCC while pressing New Inner SSCC, the inner SSCC

will be added in the level under that outer SSCC.

Sample: adding two new boxes to the pallet (..312) just created, pressing New

Inner SSCC two times:

Adding or moving items and quantities

All quantities to be fulfilled were automatically assigned to inner and/or

outer SKUs. When adding new SSCC's, there would be no item quantities available

(unassigned) to use in the new SSCC's.

However, after adding new SSCC's you can drag quantities from one SSCC to

another. For example, moving 4 units of item 1000H from box ...1511 to box

...1597:

Select the source item and hold the mouse button, then drag this item to the

target SSCC and release the mouse button:

Please make sure that you maintain the required structure. When an item has

both an outer and inner SKU, make sure the quantities you re-assign are always

placed into an inner SKU and not in an outer SKU directly.

Deleting SSCC's

You can delete existing SSCC's from the tree structure by using the button

Delete. Select the SSCC number to delete and press

Delete.

Attention: the selected SSCC and all SSCC's within it's sub tree, are deleted

without warning.

When deleting a SSCC which holds a quantity, this quantity will be placed

outside directly under the shipment number in the tree:

You will still have to create the appropriate SSCC structure for this

remaining quantity. As shown above, you can drag this quantity into an existing

SSCC.

When you close the Shipment Builder and save your changes, you can re-open

the same tree by selecting status 'Validated' in the Control Center,

selecting the appropriate sales order and pressing the

Shipment Builder button.

Shipment Builder - printing labels

Use the button Print labels to start label printing for the entire

shipment structure. The printing should start after a few seconds.

In case no labels are printed, please have a look at document

WMS SKU Management: troubleshooting label printing, the last step also applies to

AutoPack.

For testing, you can use a PDF printer in the label lay-outs or by assigning a

PDF printer in the WMS label configuration.

Please keep in mind that BarTender licensing is based on used number of

printers, when switching printers you may have to manage this situation in the

Seagull License Server.

Related documents