Introduction

This document describes the E-WMS Replenishment process, as available per product update

412.

Description

E-WMS Replenishment offers functionality to replenish stock in warehouses or on picking locations, based on either

specific minimum and maximum levels, or

based on requirements for planned fulfilments (sales orders and production

materials). E-WMS will calculate which locations or warehouse need to be replenished and, if Route Optimizing

(picking advice) is enabled, will calculate an advice to replenish these locations where serial/batch

expiration dates can be taken into account.

For the usage of E-WMS Replenishment following prerequisites apply:

- SE1381 E-WMS II

or older licenses: - SE5700 WMS Basic

- SE5705 WMS Route Optimizing (when a generated replenishment

picking advice is required)

- SE5710 WMS Replenishment

- SE5760 WMS RF

This document has following sections:

The replenishment generation process can be divided in two main parts: calculating the

requirement and calculating the

picking advice. These are two different steps before a picking advice is

send picking.

Generating replenishment orders

Requirements can be calculated either based on preconfigured fixed minimum and maximum stock levels per location

(or per warehouse), or otherwise based on 'needs' for sales orders and production

order materials. For both methods,

WMS Item Locations (or Items per WMS Location Type) need to be configured

when you are using warehouse locations. This is required to establish which locations are to be used for picking, and what quantities would maximum fit on those locations.

'Calculating requirements' is the same as 'Generating replenishment orders'.

Replenishing based on minimum and maximum levels per location

If you want to use replenishment based on preconfigured minimum and

maximum levels per location, following applies:

- WMS Replenishment

setting 'Requirements only' has to be disabled

- When working with warehouse locations: you need to configure minimum and maximum stock levels per item per location in

WMS item locations or in

WMS Items per Location type for all items and locations to be replenished

- When not working with warehouse locations, so replenishing between

warehouses: you need to configure

minimum and maximum stock levels per warehouse in Exact Globe Next item

maintenance, Inventory tab.

The rules for calculating the requirement in this case are:

- The 'trigger' to detect a shortage is comparing the available stock with the configured minimum stock

for that item

- Unprocessed WMS receipts for the target locations or warehouse are

subtracted from the quantity to replenish;

- Already generated (including status 'new') replenishment orders

are subtracted from the quantity to replenish

- Before release 408, this includes only unprocessed WMS

replenishment receipts

- From release 408, these are all unprocessed WMS receipts

(receipts, transfers, replenishment)

- 'Available stock' is the processed shelf stock

- From release 408: when the setting 'regard

picked as issued' is enabled, then this is shelf stock minus picked

but not processed (visible or physical stock)

- The quantity to be replenished depends on the WMS Replenishment

setting

'Stock Replenishment':

- If set to "Purchase order level" (minimum level) the shortage is calculated as: minimum level minus

'available' stock

- never use '0' as minimum stock, but at least '1'

- If set to "Maximum level" the shortage is calculated as: maximum level

minus 'available' stock

- When working with SKU Management then the quantity to replenish can

be rounded to a full SKU, depending on the advice

setting 'Full SKU replenishment'

Replenishing based on 'requirements only'

If you want to use replenishment based on requirements for sales orders and production

orders, following applies:

- Replenishment

setting 'Requirements only' has to be enabled

- the Replenishment

setting

'Stock Replenishment' determines to what level stock should be

replenished

- When working with warehouse locations: you need to set up minimum and maximum stock levels per item per location in

WMS item locations or in

WMS Items per Location type for all items and locations to be replenished

- From release 412, you are

able to assign the planned material issue location as replenishment

target location.

When this

setting is enabled, only the planned issue location is scanned for

requirements for this item and order.

This means you still have to configure this issue

location in

WMS item locations or in

WMS Items per Location type with minimum and maximum levels.

Only when the planned location is not filled in the material line,

replenishment will use the regular replenishment target locations.

- When not working with warehouse locations: you need to configure

minimum and maximum stock levels per warehouse in Exact Globe Next item

maintenance, tab Inventory

A typical difference of order-based replenishment compared to

replenishment based on minimum/maximum stock levels, is that the total

quantity required can be spread over all target locations, until the

total quantity needed is available. If the maximum of all target locations

is however lower than the total requirement, than the total requirement

cannot be replenished at that time. As soon as there is 'room' again on the

target locations (which can be combined with the setting 'Regard picked as

issued'), the remaining requirement can be replenished to the target

locations having room. 'Real-time

replenishment' offers the possibility to automate the process of

replenishing picking locations as soon there is room because someone picked

stock.

The rules for calculating the required quantity in this case are:

- The 'trigger' to detect a shortage is comparing the available stock

with the order requirement for that item.

- The quantity to be replenished depends on the WMS Replenishment

setting

'Stock Replenishment':

- If set to "Purchase order level" (minimum level) the shortage is

calculated as:

- the highest value of either the location minimum or the

calculated requirement for the orders

- minus already available stock or unprocessed WMS receipts

for the target location

- never use '0' as minimum stock, but at least '1'

- If set to "Maximum level" the shortage is calculated as: maximum level

minus 'available' stock

- When the

scenario setting is set to scenario 'A', then the requirement is

determined from existing picking advice for sales orders, instead of

just the entered sales orders.

Requirements for sales- or production orders

From product update 412, you have the option to generate replenishment

orders only for the requirements of sales orders, or only for requirements

of production order materials.

When generating replenishment orders in the control center, you have

several selections available based on sales orders and production orders,

including the choice 'None' for sales- or production orders.

When using Auto queue to automatically generate replenishment orders,

similar settings are available (see next section 'Auto queue for

replenishment').

Generate separate replenishment orders per target

order

From release 412, you can choose to generate

separate replenishment orders per target (sales- or production order, or

selection code).

This enables the possibility for the warehouse employee to see for which

target order he is replenishing, by using the scanner replenishment submenu

'by reference 2'. 'Reference 2' is automatically filled by E-WMS with the

target order number or selection code. When generating separate replenishment orders per

'selection code', the replenishment orders are generated per different order

type (sales/production) and per selection code. When not creating

separate replenishment orders, the replenished quantities can be a total for

several orders (bulk replenishment).

You can configure in the

WMS replenishment settings to always generate separate orders, and in

addition you can still change this when generating orders in the control

centers.

Please note that generating separate replenishment orders per target

order has some side

effects:

- status messages in the control center report (generate orders) or in

RF monitor (Auto queue service) are shown seperately per target order:

you will see more messages than without splitting orders

- depending settings and stock levels, an

incorrect target order number can be indicated in 'reference 2': when the

same item is required on the same target location, for two or more orders, and generating

replenishment orders in two or more steps.

The replenishment process does not 'remember' for which orders a

replenishment order was already generated, the quantities to replenish

are not 'allocated' to the target orders.

New replenishment orders are always first generated based on total

requirements per target location (not: requirements per order) and only after that,

optionally created as separate replenishment orders.

Therefore, generating separate replenishment orders will only work when

you are generating replenishment orders, pick and process these

replenishment orders, and then pick and process the sales- or production

orders; or when you use different target locations per production order.

To illustrate, following scenario may not show the correct target

order number in 'reference 2':

- material PART1 is required for production orders PR...01 and

PR...02, target location PR01

- a replenishment order is generated, split per target order,

resulting in two replenishment orders, with 'Reference 2' "PR...01" and

"PR...02"

- the replenishment orders are picked and processed

- new production order PR...03 is entered, also requiring material

PART1 for target location PR01

- when now generating replenishment orders split per target order,

'reference 2' may again show "PR...01"

The following scenario would show the correct target order number in

'reference 2':

- material PART1 is required for production orders PR...01 and

PR...02, target location PR01

- a replenishment order is generated, split per target order,

resulting in two replenishment orders, with 'Reference 2' "PR...01" and

"PR...02"

- the replenishment orders are picked and processed

- the materials for production order PR...01 and PR...02 are picked

and processed in E-WMS Production Issues

(removing the replenishment requirement for these orders)

- new production order PR...03 is entered, also requiring material

PART1, target location PR01

- when now generating replenishment orders split per target order,

'reference 2' will show "PR...03"

Or, because of a different target location, this scenario would also

work:

- material PART1 is required for production orders PR...01 and

PR...02, target location PR01

- a replenishment order is generated, split per target order,

resulting in two replenishment orders, with 'Reference 2' "PR...01" and

"PR...02"

- the replenishment orders are picked and processed

- new production order PR...03 is entered, also requiring material

PART1, target location PR02

- when generating new replenishment orders split per target order,

'reference 2' will show "PR...03"

Auto queue for replenishment

You can automatically generate replenishment orders and picking advices for

these orders, using E-WMS 'Auto queue'. When working with Real-time

Replenishment, the usage for Auto queue is mandatory. To work with Auto

queue, following is required:

In release 412, additional Auto queue settings 'Requirements: Sales orders'

and 'Requirements: Production orders' have been added.

Calculating replenishment advice

Once a replenishment order is generated, a replenishment advice can be (automatically) generated, depending

on the Replenishment

advice settings. The setting 'Immediate

advice' determines whether a picking advice is automatically generated, after replenishment orders have been generated.

An advice is calculated based on the settings in menu

System, General, Settings, WMS Replenishment, section Picking advice.

Even

when the setting 'picking advice' is disabled, E-WMS will still look at

actual available stock. If no advice can be generated then an error report will show and the

replenishment order (the requirement) will remain in status 'New'.

The Replenishment advice setting are explained in

this document.

Replenishment procedure

The replenishment process consists of following steps:

-

generate replenishment orders (calculate requirements)

-

generate picking advice

-

send to scanner

-

picking

-

reading back

-

validating

-

processing

'Picking' is the only step not performed in the Control Center (or by a

service). All steps except 'picking' can be automated, using the E-WMS Auto

queue service and the E-WMS Replenishment RF service.

Control center

After configuring the replenishment settings, the control center in menu WMS, To be processed, Inventory replenishment, Control center

can be started.

All steps in the control center are described in

this document.

Picking

When scanning

replenishment orders, the target location is not scanned but assumed, and is

shown as instruction text when opening an advice line.

Scanning replenishment is about scanning the stock issue.

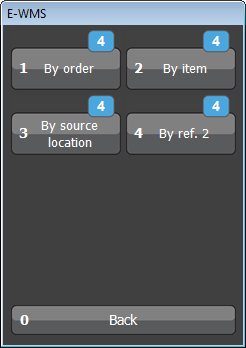

On the scanner, select menu '5 Replenishment'. Depending on scanner

settings you may see a submenu :

By using a specific submenu, you can search and scan replenishment

orders: by order (Replenishment ID), by item code, by source location or by

'Reference 2' (=target order, or selection code; from release 412).

|

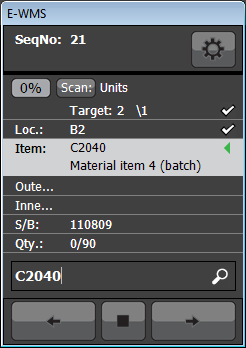

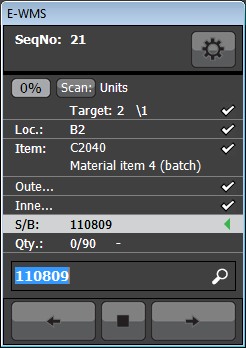

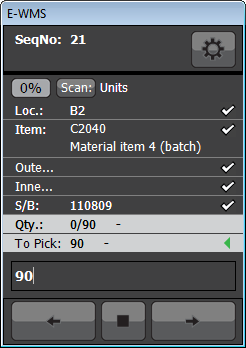

Scan item (or barcode, or SKU nr) |

Scan serial/batch if required |

Confirm quantity |

|

|

|

|

|

|

|

|

|

|

|

|

|

When all lines are done, following screen shows:

This document shows more information on general use of the WMS client

(edit or delete scanned lines, for example).

Preserving a minimum

stock level

It is possible to configure a minimum stock

level you want to preserve at the source locations or source warehouse.

Just configure 'WMS Item Locations' for these source locations,

as you would for the replenishment target locations. The 'minimum' defined

per location will not be

touched by

E-WMS Replenishment. In this case, it is necessary to replenish either only from

'bulk' type locations (to be configured in the Route Optimizing setting

'location policy') or use another warehouse as source warehouse, otherwise

there is no clear distinction between target and source locations in 'WMS

item locations'.

You can also define a minimum stock level

("Minimum PO level") at warehouse level (item maintenance, tab

'Inventory'). The usage of the minimum per warehouse can be managed by the

Replenishment setting 'Check: minimum stock'. This

minimum is only applied when replenishing to another warehouse. When you

defined minimum levels both on WMS location level and on warehouse

level, then the maximum of these two (sum of minimum location levels

versus minimum at warehouse level) will be regarded as not to be used for

replenishment.

When configuring minimum stock levels per (source) location, WMS

Replenishment will always apply and preserve these minimum levels. The

Replenishment setting 'Check: minimum stock' only applies to the

minimum level at warehouse level, not at warehouse location level.

Stock

allocations

It is possible to

exclude quantities reserved for Exact Globe Next stock allocations as available stock for replenishment. To preserve allocated

stock in the source warehouse and prevent usage of these quantities in WMS

Replenishment, enable the setting 'Include: allocated to stock'

in the general WMS Replenishment settings, section "Generate replenishment

orders". This is only applied when replenishing to another warehouse,

because stock allocations only exist on item- and warehouse level and not on

warehouse location level.

Replenishing to second warehouse while using locations

E-WMS Replenishment supports replenishing within the same warehouse, or

between two warehouses. When replenishing to more than one warehouse, please

note following:

- select 'all' warehouses in the control center Replenishment, or select

a specific issuing and receiving warehouse

- the item has to be linked to both the source and target warehouse in item maintenance,

'Inventory' tab

- 'WMS item locations' must be set up for each combination of

warehouse, location and item to be replenished

(or optional, to define minimum stock positions to preserve in the

source warehouse).

Replenishing to second warehouse without using locations

If you do not use locations, the minimum and maximum stock levels are

determined from the item/warehouse link in Inventory, Items, Maintain,

'Inventory' tab for the selected item.

Replenishing based on stock levels

The replenishment requirement will be based on the current shelf stock

and the 'minimum PO level' when the stock in this warehouse is 10 or less

(when the setting 'requirements only' is disabled) and will be filled

to the maximum (or minimum, depending on the Replenishment setting 'Stock replenishment').

When in this case the shelf stock was zero and the setting 'Stock

replenishment'

was set to 'maximum' , a replenishment advice of '50' will be the result.

Replenishment based on requirements

When the setting 'Requirements only' is enabled, the requirement

will be based on currently planned fulfillments for sales- and production

orders from this warehouse.

When the setting 'Stock replenishment' is set to maximum level, the requirement is

always the maximum defined for this warehouse (even when this is less or

more than required for fulfillment).

When the setting 'Stock replenishment' is set to minimum level, then the

requirement is either the minimum level set for the warehouse or the

quantity required for fulfillment (the highest value is applied).

When the

maximum level set for the warehouse is less than the requirement, then the

maximum will be advised - more items "will not fit".

See sample scenario's 6, 7 and 8 below.

Sample scenario's

In all scenario's, locations P1 - P4 are locations of type 'pick location', and locations B1 - B4 and 'REC' are locations of type 'bulk location'.

Item code '1000' is a standard (non serial/batch) item.

Scenario 1: replenishing within one warehouse based on minimum and maximum stock positions, to maximum level

| Stock positions item code '1000' |

| location |

shelf stock |

WMS minimum stock |

WMS maximum stock |

|

| P1 |

10 |

30 |

50 |

|

| P2 |

0 |

30 |

50 |

|

| P3 |

20 |

30 |

50 |

|

| P4 |

5 |

30 |

50 |

|

| |

|

|

|

|

| B1 |

50 |

- |

- |

|

| B2 |

50 |

- |

- |

|

| B3 |

50 |

- |

- |

|

| B4 |

100 |

- |

- |

|

| REC |

250 |

- |

- |

|

There are no sales orders open for this item.

Active replenishment settings:

The setting 'Requirements only' is disabled, so requirement would be calculated based on minimum and maximum stock positions.

The setting 'Stock replenishment level' is set to "maximum level", so the pick locations should be replenished to the maximum level when the stock level drops below the minimum.

Advice generation in this case:

| From location |

to location |

quantity |

why |

| B1 |

P1 |

40 |

current stock=10, need 40 to reach maximum 50 |

| B2 |

P2 |

50 |

current stock= 0, need 50 to reach maximum 50 |

| B3 |

P3 |

30 |

current stock=20, need 30 to reach maximum 50 |

| B4 |

P4 |

45 |

current stock= 5, need 45 to reach maximum 50 |

Scenario 2: replenishing within one warehouse based on minimum and maximum stock positions, to minimum level

Same stock positions as in scenario 1, no sales orders.

Active replenishment settings:

The setting 'Requirements only' is disabled, so requirement would be calculated based on minimum and maximum stock positions.

The setting 'Stock replenishment' is set to "purchase order level" (minimum level), so the pick locations should be replenished to the minimum level.

Advice generation in this case:

| From location |

to location |

quantity |

why |

| B1 |

P1 |

20 |

current stock=10, need 20 to reach minimum 30 |

| B1 |

P2 |

30 |

current stock= 0, need 30 to reach minimum 30 |

| B2 |

P3 |

10 |

current stock=20, need 10 to reach minimum 30 |

| B2 |

P4 |

25 |

current stock= 5, need 25 to reach minimum 30 |

Scenario 3: replenishing within one warehouse based on 'requirements only', to maximum level

Same stock positions as in scenario 1, one sales order for quantity 60.

Active replenishment settings:

The setting 'Requirements only' is enabled, so the requirement is calculated from sales orders and production

orders

The setting

"Stock replenishment' is set to "maximum level", so the pick locations

should be replenished to the maximum level

Advice generation in this case:

| From location |

to location |

quantity |

why |

| B1 |

P1 |

40 |

current stock=10, need 40 to reach maximum level 50 |

Adding 40 to P1 gives a total stock of 75 (P1:50, P3:20, P4:5) , filling P1 to the maximum and total enough for fulfillment.

Scenario 4: replenishing within one warehouse based on 'requirements only', to minimum level

Same stock positions as in scenario 1, one sales order for quantity 60.

Active replenishment settings:

The setting 'Requirements only' is enabled, so requirement is calculated from sales orders and production

orders

The setting 'Stock replenishment' is set to "purchase order level" (minimum

level), so the pick locations will be replenished to the minimum level, or

to the quantity required for the orders

Advice generation in this case:

| From location |

to location |

quantity |

why |

| B1 |

P1 |

25 |

current stock=10, need 25 to reach 35 |

Adding 25 to P1 gives a total stock of 60 (P1:35, P3:20, P4:5) , enough for fulfillment.

Scenario 5: replenishing to other warehouse while using locations, based on minimum and maximum level, to maximum level

| Stock positions item code '1000' |

| warehouse |

location |

shelf stock |

WMS minimum stock |

WMS maximum stock |

|

| 1 |

P1 |

10 |

30 |

50 |

|

| 1 |

P2 |

0 |

30 |

50 |

|

| 1 |

P3 |

20 |

30 |

50 |

|

| 1 |

P4 |

5 |

30 |

50 |

|

| 1 |

B1 |

50 |

- |

- |

|

| 1 |

B2 |

50 |

- |

- |

|

| 1 |

B3 |

50 |

- |

- |

|

| 1 |

B4 |

100 |

- |

- |

|

| 1 |

REC |

250 |

- |

- |

|

| |

|

|

|

|

|

| 2 |

P1 |

0 |

30 |

50 |

|

| 2 |

P2 |

0 |

30 |

50 |

|

| 2 |

P10 |

0 |

60 |

100 |

|

Active replenishment settings:

The setting 'Requirements only' is disabled, so the requirement is

calculated from minimum and maximum location stock levels

The setting 'Stock replenishment' is set to "maximum level"

Control Center Replenishment selection: issuing warehouse = "1", receiving warehouse = "2". Advice generation in this case:

| From wh/loc |

to wh/loc |

quantity |

why |

| 1 / B1 |

2 / P1 |

50 |

current stock= 0, need 50 to reach maximum |

| 1 / B2 |

2 / P2 |

50 |

current stock= 0, need 50 to reach maximum |

| 1 / B4 |

2 / P10 |

100 |

current stock= 0, need 100 to reach maximum |

| |

|

|

|

Source location 'B4' has enough to pick '100' in one 'stop', this advice depends on the

picking advice settings for Replenishment.

When changing the advice settings to 'make locations empty', the advice is calculated as:

| From wh/loc |

to wh/loc |

quantity |

why |

| 1 / B1 |

2 / P1 |

50 |

current stock= 0, need 50 to reach maximum |

| 1 / B4 |

2 / P2 |

50 |

current stock= 0, need 50 to reach maximum |

1 / B2 +

1 / B3 |

2 / P10 |

50 + 50 |

current stock= 0, need 100 to reach maximum |

| |

|

|

|

| |

|

|

|

Scenario 6: replenishing to other warehouse, warehouse locations not

used, based on minimum and maximum level, to maximum level

| Stock positions item code '1000' |

| warehouse |

|

shelf stock |

WMS minimum stock |

WMS maximum stock |

|

| 1 |

|

150 |

0 |

0 |

|

| 2 |

|

0 |

30 |

50 |

|

| |

|

|

|

|

|

The minimum and maximum stock levels are set in Item Maintenance, tab

'Inventory', properties of warehouse '2'.

Active replenishment settings:

The setting 'Requirements only' is disabled, so the requirement is calculated from minimum and maximum

stock levels

The setting 'Stock replenishment' level is set to "maximum level"

Control Center Replenishment selection: issuing warehouse = "1", receiving warehouse = "2". Advice generation in this case:

| From wh |

to wh |

quantity |

why |

| 1 |

2 |

50 |

current stock= 0, need 50 to reach maximum |

| |

|

|

|

Scenario 7: replenishing to other warehouse, warehouse locations

not used, based on

requirements, to minimum level

| Stock positions item code '1000' |

| warehouse |

|

shelf stock |

WMS minimum stock |

WMS maximum stock |

|

| 1 |

|

150 |

0 |

0 |

|

| 2 |

|

0 |

30 |

50 |

|

| |

|

|

|

|

|

The minimum and maximum stock levels are set in Item Maintenance, tab

'Inventory', properties of warehouse '2'.

There is one sales order (approved and confirmed) to be fulfilled from

warehouse 2 for quantity 40.

Active replenishment settings:

'Requirements only' is enabled

'Stock replenishment' is set to "purchase order level" (minimum

level)

Control Center Replenishment selection: issuing warehouse = "1", receiving warehouse = "2". Advice generation in this case:

| From wh |

to wh |

quantity |

why |

| 1 |

2 |

40 |

current stock= 0, need 40 for fulfillments from

warehouse 2 |

| |

|

|

|

Scenario 8: replenishing to other warehouse, warehouse locations not

used, based on

requirements, to minimum level, but requirement is higher than maximum

| Stock positions item code '1000' |

| warehouse |

|

shelf stock |

WMS minimum stock |

WMS maximum stock |

|

| 1 |

|

150 |

0 |

0 |

|

| 2 |

|

0 |

30 |

50 |

|

| |

|

|

|

|

|

The minimum and maximum stock levels are set in Item Maintenance, tab

'Inventory', properties of warehouse '2'.

There is one sales order (approved and confirmed) to be fulfilled from

warehouse 2 for quantity 75.

Active replenishment settings:

'Requirements only' is enabled

'Stock replenishment' is set to "purchase order level" (minimum

level)

Control Center Replenishment selection: issuing warehouse = "1", receiving warehouse = "2". Advice generation in this case:

| From wh |

to wh |

quantity |

why |

| 1 |

2 |

50 |

current stock= 0, need 75 for fulfillments from

warehouse 2, |

| |

|

|

but maximum for this warehouse is 50 |

| |

|

|

|

Troubleshooting

When generating replenishment orders does not show the items or

quantities you expected, then

this document has some troubleshooting tips.

Related documents